The Liner Diameter Measurement (LDM) tool is an essential service for ship engine maintenance, focusing on detecting abnormal wear and deformation caused by operational changes like slow-steaming or the use of new lubricating oils. Designed for 2-stroke engines with a bore size ranging from 500 to 980 mm, the LDM allows for precise measurements without needing to remove the cylinder cover or exhaust valve housing.

Available for MAN B&W, Wartsila, and Mitsubishi 2-stroke engines, the LDM is a versatile and reliable tool for ensuring optimal engine health.

With this highly efficient tool, our service team can complete the job swiftly and with only one technician.

The LDM’s ability to quickly identify wear and deformation is invaluable for addressing potential issues before they escalate. It is particularly useful for checking engine conditions before dry-docking or as part of regular maintenance checks.

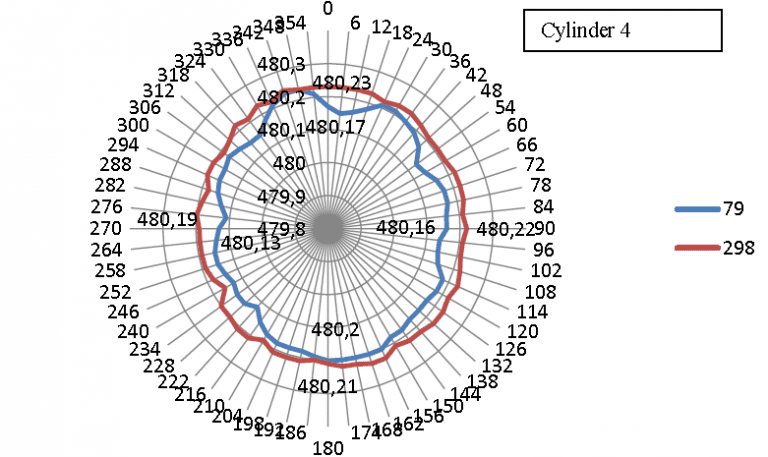

With its advanced clover-leafing measurement feature, the LDM detects non-oval wear and deformation, including issues like:

- Heat-induced deformation from slow-steaming retrofitting

- Injector erosion

- Uneven lubricating oil distribution.

The LDM is available for MAN B&W, Wartsila and Mitsubishi 2-stroke engines with a cylinder bore of 500 to 980 mm.

please contact us at mftservice@marinefluid.dk