Introduction

About SEA-Mate® Blending-on-Board

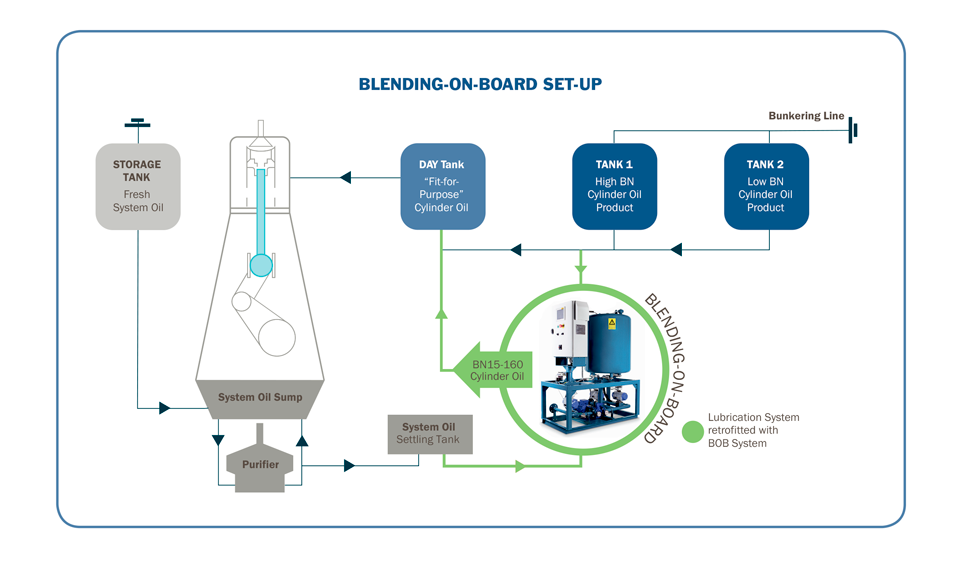

The SEA-Mate® Blending-on-Board System is an Innovative concept compared to conventional lubrication practices. The key difference being that BOB addresses both Crankcase and Cylinder lubrication needs at the same time, without the need to maintain and store multiple lubricant products onboard the vessel.

The SEA-Mate® BOB equipment puts control firmly back into the hands of the operator by providing greater flexibility in terms of their lubricant options to accommodate the many technical challenges faced onboard a modern vessel.

The equipment is designed to produce a finished Cylinder lubricant to a targeted specific Base Number at the flick of a switch. It really is as easy as that, as a lot of time and effort has been invested into making the equipment user friendly and simple to operate.

The concept enables the operator to continuously adjust and optimize the lubricant neutralization characteristics in accordance with the engine requirements and fuel sulphur content.

Constant replenishment of the engine crankcase with fresh, new System Oil will ultimately lead towards cleaner oil in circulation with a consequent improvement in viscometrics and related improved fuel economy. Cleaner oil will promote cleaner engine crankcases and longer critical component life time. Other related benefits are:

- Reduced fuel consumption is better for the environment, reducing CO2 emission.

- Lower levels of contamination or dirt ingress requiring reduced reliance on intensive centrifuge operation. In some circumstances the centrifuge could be replaced by conventional filter medium instead.

Fuel saving 1,5%

On a typical large bore engine, fuel saving coming from SEA-Mate® Blending on Board will amount annually to USD 100,000 – 149,000

Benefits from Blending-on-Board

- Proven fuel savings on board as result of fresh system oil - Actively consuming system oil for Blending-on-Board means no increase in system oil viscosity (friction) over time. Lower system oil friction translates into proven & documented fuel savings on board up to 1.5%. Read the report here

- Keeps system oil additives fresh and contamination at a minimum. Reduce lubrication oil by recycling of lube oil. Actively consuming system oil for Blending-on-Board means fresh and active system oil is added to system oil sump with regular intervals. This reduces contamination of oil and thus ensures better lubrication everywhere. Read more here

- Fit-for-Purpose base-number assists in solving cylinder liner cold corrosion challenges and reduce liner & piston ring wear. Read more here

- Reduce engine lubrication oil consumption up to 40%, by reusing engine lubrication oil. For most MAN B&W 2-stroke engines it is possible to achieve 0,6 g/kWh feed regardless of sulphur content, for Wärtsilä 2-stroke engines down to 0,7 g/kWh can be achieved. Standard lubrication settings often result in lube-oil consumption of 1.2 g/kWh or more when running on high-sulphur fuel.

Solutions Available

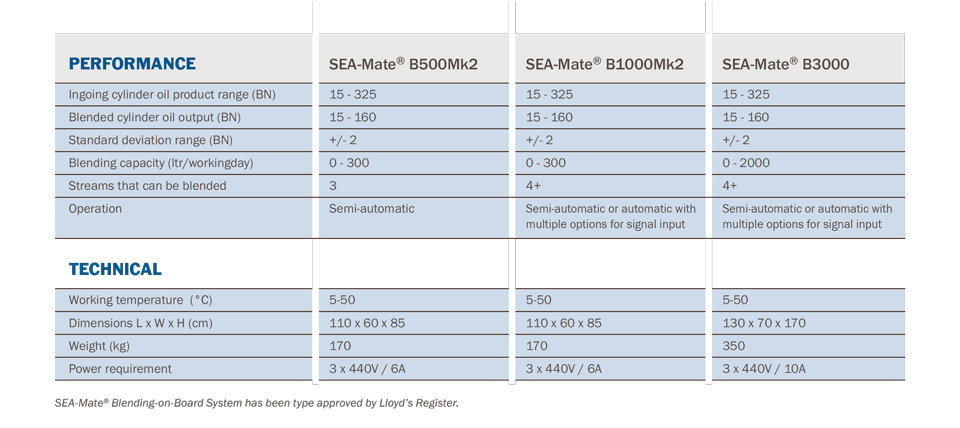

Small & Medium-Bore (up to 600 mm bore engines): Sea-Mate B1000

Large-bore (up to 980 mn bore engines): Sea-Mate B3000

Advantages

SEA-Mate® Blending-on-Board for 2-stroke marine and powerplant engines facilitates significant Lube-Oil cost and consumption, reduced engine component wear and is environmentally friendly – all with a payback time of 1-2 years.

Key Benefits

- Up to 40% Lube-Oil Savings

Automatic blending of optimal cylinder oil allows running at or close to specified “minimum lubrication” at all times, regardless of fuel sulphur content. Adding fresh system oil frequently reduces purifier waste by up to 40%. - Up to 1.5% Fuel Savings

With BOB, the engine sump system oil is continuously refreshed. Fresh oil equals less friction and proven fuel savings on board. - Mitigate Cold Corrosion

200+ installations and performance monitoring, has proved that adaptive adjustment of cylinder oil acid neutralizer (BN) is a powerful way to mitigate liner wear. - Reduced Maintenance CostsTo reduce the maintenance cost on vessel, simply optimized system and cylinder liner lubrication and thereby eliminate unnecessary deposits and fouling. This will lead to increasing lifetime of components like piston rings significantly.

-

Proven Concept

3rd Generation Equipment, 200+ installations. Millions of cylinder running hours logged.

- Lube-Oil Supplier Independence

Blending-on-Board works with high BN cylinder oil products from any supplier. - Easy to Install and Use

Class and engine designer approved system can be fitted within a regular port-stay. Operation is easy and BOB runs fully automatically.

Product Specifications

Integration & Configuration

The system is run under semi-automatic operation, which gives you the opportunity to monitor the blender operation as you go along. The Programmable Logic Controller functions as an extra quality control that reacts to unforeseen events.

It is designed to plug right into the existing alarm system and will stop blending in case of an unlikely mechanical breakdown.

The control system contains all necessary security and safety features and comply with any Class Society requirement.