Introduction

“Introducing the SEA-Mate® Analyzer – a novel analyzing lubricant and fuel sulfur analysis device”.

The SEA-Mate® Analyzer provides incipient failure detection and fluid quality control within minutes. The need for continuous monitoring of an engine’s performance is not to be taken lightly. Therefore the SEA-Mate® Analyzer was developed, putting this critical diagnostic process under your control and not in the hands of a third party. The SEA-Mate® Analyzer is designed for analyzing lubricants and fuel sulfur. A precise and reliable cylinder oil consumption Monitoring System.

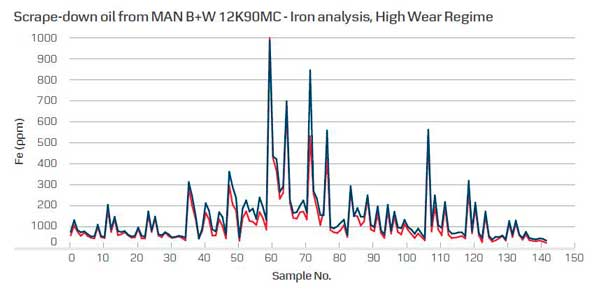

The SEA-Mate® Analyzer is the only way to immediately detect corrosive engine wear, typically seen during slow steaming and in newer engine design. Knowing the true iron content is critical to optimize engine performance, finding the right cylinder oil BN & feed rate needed. This will lengthen cylinder liner and piston ring life time, reducing spare parts and maintenance cost.”

A unique bar code sticker is attached to every sampling point on the engine and other machinery for which oil analysis and trending is to be carried out. Each time a sample is taken a hand-held bar code reader is used to match the sample point with another bar code label on the sample bottle.

After collecting samples, the bar code reader is hooked up to the SEA-Mate® terminal and the system’s software links the individual samples to the appropriate sample point in the system database recording time and date of sampling at the same time. When the sample bottle is placed in the machine and analysed the results are recorded in the database.

As the database is populated with sample results it is possible to analyse trends over time periods of the operator’s choice. When an engine is involved, samples can be taken from every cylinder so that trend analysis can be made either for the whole engine or for specific areas within it. This will permit easier identification of a problem and its likely cause.

Advantages

Advantages of using the SEA-Mate® Elemental Analyzer include:

- Elemental analysis for large transportation and land-based power generation.

- Optimization of oils, additives usage, and predictive maintenance

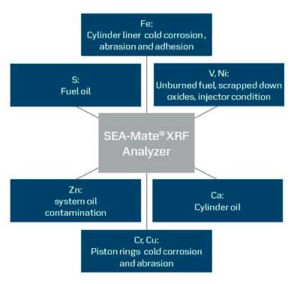

- Early detection of abnormal wear from metals such as Fe, V, Cu, Cr, Ni and Pb

- Enables control of oil & additive usage to blend to precise alkalinity levels

- Analyzes S in fuels when bunkering

As well as its function of almost instant bunker testing, trend analysis is a strong feature of the SEA-Mate® X-Ray analysis system. Condition based maintenance is becoming increasingly popular because it has the capacity to reduce both the quantity of spare parts consumed and the number of man hours spent on unnecessary strip downs. Analysis of wear metals in engine lube samples is one of the best means of practicing Condition Based Monitoring because it provides better indications of the internal health of the engine without the uncertainty that extending TBOs based on predicted component life has.

Specifications

| Weight: | 27 kg (including mounting hardware) |

| Excitation source: | X-Ray tube, Ag anode, 10 kV up to 40 kV, 4W max. |

| Detector: | Si PiN diode detector, <220 eV FWHM at 5.95 keV Mn K-alpha line |

| Temperature range: | 5 to 40° C |

| Operation: | Integrated NEMA 4; Windows-based PC |

| Power Requirements: | 110-250V @ 50/60 Hz (uses European and US power standards) |